Live Edge Wood For Sale

So, you’re driving around and see a sign advertising live edge wood for sale. You always wanted to build something with live edge wood so you decided to stop in and pick out a slab. If you’re new to woodworking, picking out a slab can be tricky. There are a lot of sawmills that sell sub-par material that will turn your exciting new woodworking project into a nightmare. Here are the most important things to look for when picking out a wood slab for your next project!

Has the Wood Slab been kiln dried?

The first step to buying any lumber used for the creation of furniture is to ensure that the lumber was properly dried. By drying, the lumber is stabilized so that it will not warp or crack after it is finished. When wood is not dried or improperly dried, your finished piece of furniture will warp, crack and split. The drying process is the biggest bottleneck of a lumber supply business and unscrupulous mills may cut corners when drying and sell an inferior product. Wood slabs should be dried to between 6-8% moisture content ensuring a stable and workable product.

Another aspect to consider is how the wood was kiln dried. There are three major types of kilns sawmills use to dry lumber. Dehumidification, Vacuum and Steam. There are many advantages and disadvantages for each type in terms of drying speed, cost and resulting lumber quality. Out of these methods we have found that the dehumidification kiln produces the best results. Both the steam and vacuum kilns are able to dry lumber in around half the time, however they produce a duller color in the wood and can cause honeycomb cracks throughout the interior of the wood. Furthermore, the vacuum kiln oftentimes hydraulically clamp the drying stacks and this can preserve the tension in the slabs during the drying process. This can result in the wood slabs cupping or twisting even after being dried. This is why we dry all of our slabs using a dehumidification kiln. It may take longer but here at Wood Slabs; we strive to provide our clients with only the best live edge wood slabs. We do not only sell the slabs but also have a wood shop on site where we build one-of-a-kind pieces of furniture.

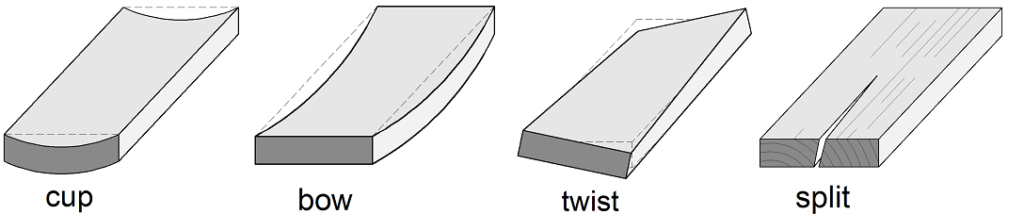

Once you confirm that the slabs were dried, next you should carefully examine the live edge slab you’re interested in for drying defects. Drying defects will be present in 100% of any dried lumber. Lumber will always move in the kiln during the drying process. The key is to be purchase a slab that has minimal defects that can be fixed during furniture production. See below the most common defects you will find when shopping for live edge wood.

No wood slab is perfectly flat before its worked. The key is for the wood slabs to be thick enough where the drying defects can be removed. We mill all our lumber to between 2.25-2.75 inches thick (depending on slab size) so that we achieve a finished thickness of around 2 inches. When shopping for live edge wood always account for the thickness you may lose to dressing the lumber. When picking out your slab make sure that the cup, bow or twist is not severe enough to make the piece of lumber not usable. The last defect you will run into is the split. This is a fairly common defect in live edge wood as the slabs are often wide with a great deal of tension. When the slab shrinks in the kiln it can develop a crack. This defect is easily fixed with epoxy inlay.

When shopping for live edge slabs or dimensional lumber please remember to consider all of the above before making your purchase. If you are in the greater Toronto area and are interested in high quality wood slabs feel free to contact us to arrange a viewing. We also ship across Canada.

lets talk live edge wood slabs

Feel free to call or text Mike at (416) 618-0081